Our picks for the Top Roadbuilding Equipment for 2019 | Dump Truck Company

This has been a solid year for new roadbuilding equipment, with introductions from Cat, Wirtgen, Roadtec and most of the major manufacturers.

We compiled a roundup of product rollouts that have appeared on charlotte nc dump trucks world.com in 2019 to date, to provide a quick overview of some of the new charlotte nc dump trucks on the market.

PAVERS

BOMAG CR 1030 W

Dual swingout operator stations

BOMAG’s new line of highway-class wheeled and tracked pavers feature dual swingout operator stations and other innovations to give operators better views of their work.

The pavers’ introduction also streamlines the company’s 10-foot lineup from four pavers to two models – one wheeled, the CR 1030 W, and one with rubber tracks, the CR 1030 T.

They are designed for such projects as interstate and state highways, airports, heavy industrial and large commercial. They replace BOMAG’s CR 452, CR 552, CR 462 and CR 562 pavers.

Eliminate daily cleaning under hopper

Carlson Paving gave its CP75 II a high-flow material conveyor and frame design that does not require hydraulically lifting hoppers – eliminating the need for daily cleaning under the hopper. Instead, operators only need to inspect the undercarriage every 500 hours to ensure there is no buildup. The conveyor system, which pairs belt technology with a heavy-duty chain and slat conveyor, is designed for longer life and greater efficiency. Carlson also replaced all the operator controls with toggle switches for a more intuitive feel.

Increase paving distance by one-third

Dynapac North America’s FC1700C commercial-class paver is equipped with a larger Tier 4 Final, 120-horsepower Cummins engine than the FC1600C model it replaces. Its hood profile offers best-in-class visibility to the hopper. A lower conveyor dumping height and larger 9.5-ton hopper capacity increase paving distance by one-third before reloading the hopper is necessary. The wider 14-inch track pads improve traction when paving on soft surfaces by reducing ground pressure. New operator controls are more intuitive.

2 tons more hopper capacity

Mauldin’s 1860, the largest in its lineup of asphalt pavers, replaces the company’s former largest paver, the 1750-C. One of the main differences between the two models is the 1860’s larger hopper size. It can handle 9.5 tons of material versus the 1750’s 7.5 tons. The 1860 maintains the company’s Silver 16 Screed, which is the heaviest in its class at 4,500 pounds. Mauldin moved all controls to the two individual operator stands. Each operator stand has a 5-inch display screen. The tracks have been upgraded from 12- to 14-inch track pads.

Wheeled paver pushes like tracks

Roadtec’s wheeled 10-foot RP-250e asphalt paver is designed to provide the same pushing power as a tracked paver, the dump trucks charlotte nc says. To achieve this, Roadtec gave the heavy-duty paver a 250-horsepower engine and large diamond-tread, high-flotation drive tires. The paver also has an adjustable frame-raise feature for weight distribution and tractive effort. The RP-250e comes with the same features as Roadtec’s other pavers. These include the company’s anti-segregation design of its feed tunnel, feed tunnel discharge and rear augers.

Access tight spaces

Weiler designed the screed on its P195 asphalt paver for mat quality and a range of paving widths. The 3-foot, 10-inch front-mount screed can be hydraulically extended to 7 feet, and to 9 feet with bolt-on extensions. The 80-inch-long tracks deliver 64 inches of ground contact and, with a 125-milimeter track chain pitch, provide a smooth ride and increased flotation. Weiler added automatic track tensioning. All controls are on a single panel within reach of the operator. The paver’s narrow design allows for simple transport and accessing tight spaces.

Remote-control bridge paving

Terex Bid-Well unveiled its 3600RC remote-control paver designed for paving bridge decks, as well as flatwork and roads. The paver can be operated remotely from the ground, and the operator can adjust machine settings without having to call down to a worker to make the change or to stop paving operations. The remote control governs engine, power legs, machine and carriage travel-speed functions and can also control accessories. It has a maximum paving width of 86 feet, a truss depth of 3 feet and an operating weight of 7,760 pounds.

Turn on the spot

Wirtgen’s SP124i slipform concrete paver has a working width of 39 feet with four steerable and slewing crawler units and an optional slew drive steering system with a steering angle of up to 260 degrees. This maneuverability allows paving beside a building, turning almost on the spot without wasting time on repositioning. The paver is powered by a 420-horsepower Cummins diesel engine and can pave from 14.5 to 39.3 feet wide and up to 17.7 inches thick. Options include a self-loading dowel bar inserter with fully automated dowel magazine.

ROLLERS

Compact beside structures and obstacles

Case’s Tier 4 Final DV23CD combi roller has nearly 20 inches of curb clearance, an oscillating articulation joint for drum-to-ground contact, and no overhangs, which allows charlotte nc dump truck company beside structures and obstacles. The hydrostatically driven front drum comes standard with dual-frequency, automatic or manual vibration control, and features a tapered drum edge to minimize tearing through turns. The rear pneumatic tires can be paired with an ACE Force Intelligent Compaction System for precise results.

Hamm HP 180

Work a day without refilling water, diesel tanks

Hamm’s new generation of pneumatic tire rollers include the HP 180, HP 280 and HP 280i, with operating weights between 10 and 28 tons. They feature a variable ballasting concept, which allows you to adjust the operating weight to match the asphalt type, thickness and application by adding or removing steel, magnetite or concrete ballast bodies between the axles. The ballast components are mounted in the center of the machine to evenly distribute weight. The rollers’ water and diesel tanks are sized to last the day without refilling.

MILLING

Cat PM313

Sliding operator stations

Caterpillar gave its PM310, PM312 and PM313 cold planer models a boost in power, as well as added new features. The milling machines are now available with a 334-horsepower Tier 4 Final C9.3 engine, for a 3 percent increase in power. Cat designed the planers for small to mid-sized jobs where maneuverability and high production are needed. They come in wheeled or tracked versions. The cold planers feature operator stations that slide out 8.5 inches beyond the frame for improved visibility down. The seat also now has a right-side armrest for comfort.

Boost in power

Roadtec updated the RX-700e cold planer with an 800-horsepower Tier 4 Final engine that requires no diesel exhaust fluid. The Caterpillar engine on the half-lane cold planer replaces the 755-horsepower Tier 4 Interim engine on the previous model. The planer cuts up to 14 inches deep with standard widths of 6 feet 7 inches, 7 feet 2 inches, 8 feet 2 inches and 10 feet 6 inches. The RX-700e is available in three- or four-track models. The cutter housing’s angled moldboards reduce wear by preventing material from accumulating around the drum.

Wirtgen W 210 Fi

Change milling drums in 15 minutes

Offering milling widths from 4.9 to 8.2 feet and milling depths of up to 13 inches, Wirtgen‘s W 210 Fi, W 200 Fi and W 200 F models are equipped with engines rated up to 755 horsepower and a high-torque output at 1,300 rpm. A quick-change milling drum assembly enables you to change out different width drums in as little as 15 minutes. The drum side door opens hydraulically, and a loosening tool is positioned on the main bolt. Push a button and the tool loosens the main bolt, enabling you to pull out the milling drum.

ADDITIONAL ROAD EQUIPMENT

Loaded, hexagonal cab

Komatsu’s GD655-7 motor grader features a “hexangular” cab for increased visibility. The cab viewing area has a narrow center section and two clear doors on the sides. Electronic controls are situated back toward the seat in a more relaxed position for the operator, instead of an upfront antler rack configuration. Komatsu made the cab quieter and loaded it with such standard features as power raise and lower for the left-hand and right-hand consoles, multi-position adjustable armrests, air-suspension seat and rearview camera.

More power for reclamation, soil stabilization

Caterpillar’s RM400 Rotary Mixer gets a 19 percent boost in power over the RM300, which it replaces, with a 417-horsepower Tier 4 Final Cat C9.3 engine. Cat also improved the cab, which can slide right and left for side views of the tire edges and cut lines. The dump trucks charlotte nc provided standard front and rear cameras and optional side-mounted cameras. Cameras can also be mounted in front and behind the rotor chamber. The 51,809-pound RM400 has a cutting width of 8 feet and is designed for full-depth reclamation and soil stabilization.

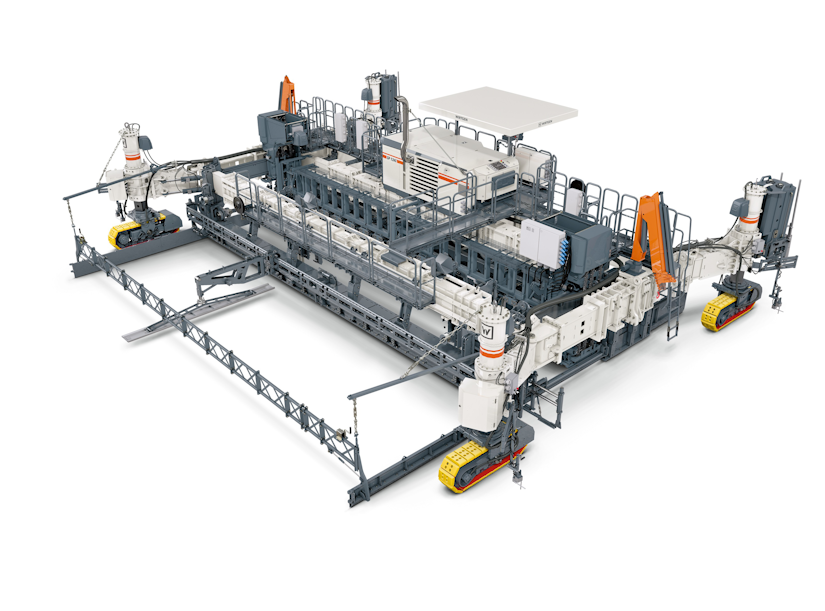

W 380 CRi

Environmentally friendly road recycler

Wirtgen designed its W 380 CRi cold recycler to rehabilitate roads quickly and economically while reusing the paving material in an environmentally friendly way. The cold recycling process grinds and reuses the surface and base materials of a deteriorating road and mixes it with binding agents, such as cement, bitumen emulsion or foamed bitumen. With working widths of 126, 138 and 150 inches and recycling depths of 4 to 12 inches, the W 380 CRi can feed up to 800 tons an hour of material to a paver via its swivel-mounted, height-adjustable conveyor.

Automatically adjusts to paver distance

Dynapac’s MF2500CS material transfer vehicle features automated operation, low fuel consumption and less maintenance than previous models. Lasers on the MTV allow the operator to switch to auto mode, and the MTV’s conveyor will automatically keep the proper distance from the paver’s hopper. A sensor can also be placed on the front, so the MTV will automatically steer along a curb line or concrete barrier. Dynapac also automated the loading of the MTV. The operator hits a couple of buttons, and lights flash to guide the truck driver.

PAVING TECHNOLOGY

Push a few buttons and let it roll

Caterpillar unveiled an automated soil compaction system that allows the operator to simply tap a few buttons to get the compactor automatically rolling, rather than having to input loads of data. The Command for Compaction system’s touchscreen for Cat’s B-Series vibratory soil compactors enables the operator to set parameters, hit “auto,” and the compactor takes over the steering, keeping the compactor rolling forward or in reverse over the desired path. The system also includes an automatic object-detection system that alerts the operator to obstacles.