Autocar reenters construction dump market with made-to-order DC-64D | Dump Truck Company

Custom-truck-builder Autocar is reentering the construction dump market with its DC-64D.

Custom-truck-builder Autocar is reentering the construction dump market with its DC-64D.

“This is not a stock truck,” says Tim Thornton, Autocar’s vice president of strategy and commercialization. “All of our trucks are made to order, from the axle configuration to the controls and body type. We do as much pre-engineering up front with the body companies,” Thornton says. “We actually build the chassis and frame rail so the upfitter doesn’t have to weld or cut.”

Tapping into the expertise of an advisory construction board – which included a number of concrete supply and concrete dump trucks charlotte nc – DC-64D designers created a “from the ground-up vocational specific truck,” Thornton says.

This made-to-order approach to truck manufacturing is a process that usually takes 3 to 4 weeks from a customer-approved spec to the end of the production line. If it’s an existing spec the process goes more quickly, but more complex designs—such as the 6×8 twin-steer dump ordered by a Canadian firm—take longer.

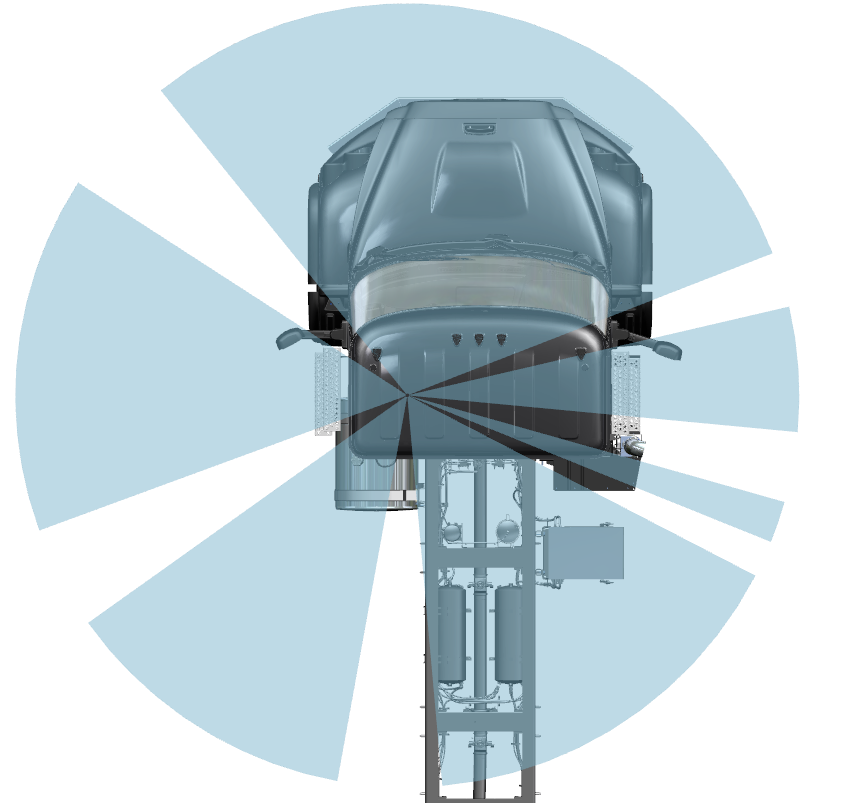

This up-front time is well worth the end result and premium cost, Autocar argues. By matching the truck with the specific body, features such as the DC-64D’s wraparound windshield and 325-degree visibility from the cab can be fully exploited.

The Autocar DC-64D has 325-degree visibility, says the company.

As an example of how much visibility its cab offers to contractors, Autocar is partnering with R/S-Godwin Truck Body to promote the DC64-D along with Godwin’s sloped construction and hybrid bodies. These bodies have a sloped bulkhead that provides better visibility because of the increased cab-to-body setback. Also helping visibility is the truck cab’s rear-corner wrap-around windows.

The cab’s 7-inch driver information Smart Display offers benefits for both drivers and technicians, says Autocar. For drivers, a no-distraction mode helps drivers stay focused on the job; drivers can also select their preferred level of information to reduce distractions. For technicians, the display provides electrical diagnostic reports on any any failed fuses/circuits, along with access to service manuals, wiring schematics and 3D diagrams.

Built for severe duty

Autocar emphasizes the severe-duty nature of the DC-64D.

With its 6-inch shocks on the bottom of the welded steel cab combined with a horizontal stabilizer bar, the truck provides additional stability over competitive trucks, says the company. The door structure and handle can support 450 pounds of weight and the door hinges and A-pillar design uses oversized fasteners with piano-type hinges to withstand severe-duty use.

The truck’s frame rail is made with 160,000-psi yield strength material and the front tow pins can handle 80,000-pounds of towing capacity.

On the electrical side, battery cables are routed by themselves to avoid rubbing. Autocar uses water-sealed connectors throughout the truck to keep water and dirt out. A Hellerman Titan clamping system supports the harness every 12 inches to prevent rubbing and chafing.

The gas-strut-assisted hood requires less than 10 pounds of pull force to open, tilt or close. Standard dual Sheppard M100 steering gears are rated for 28,000 front GAWR; a 112-inch BBC and up-to-50-degree wheel cut provide a tighter turning radius.

Service philosophy

Thornton says Autocar has an unusual service philosophy. “Our goal is to build a truck that never breaks down and then not profit from our customer’s downtime,” Thornton says. “We provide service as a component of the price of the truck and we provide it for the life of the truck.”

While sales are handled from the factory, service is provided both factory direct and through 450-plus authorized service locations.

Autocar’s own technicians are on call 24/7. An 800 number connects customers to a technician, who provides over-the-phone assistance, replacement part ordering and training. The dump trucks charlotte nc also avoids proprietary componentry and most parts are off-the shelf and readily available. Autocar outfits the DC-64D, for example, with Cummins X12 or L9 engines and Meritor and Allison transmissions.

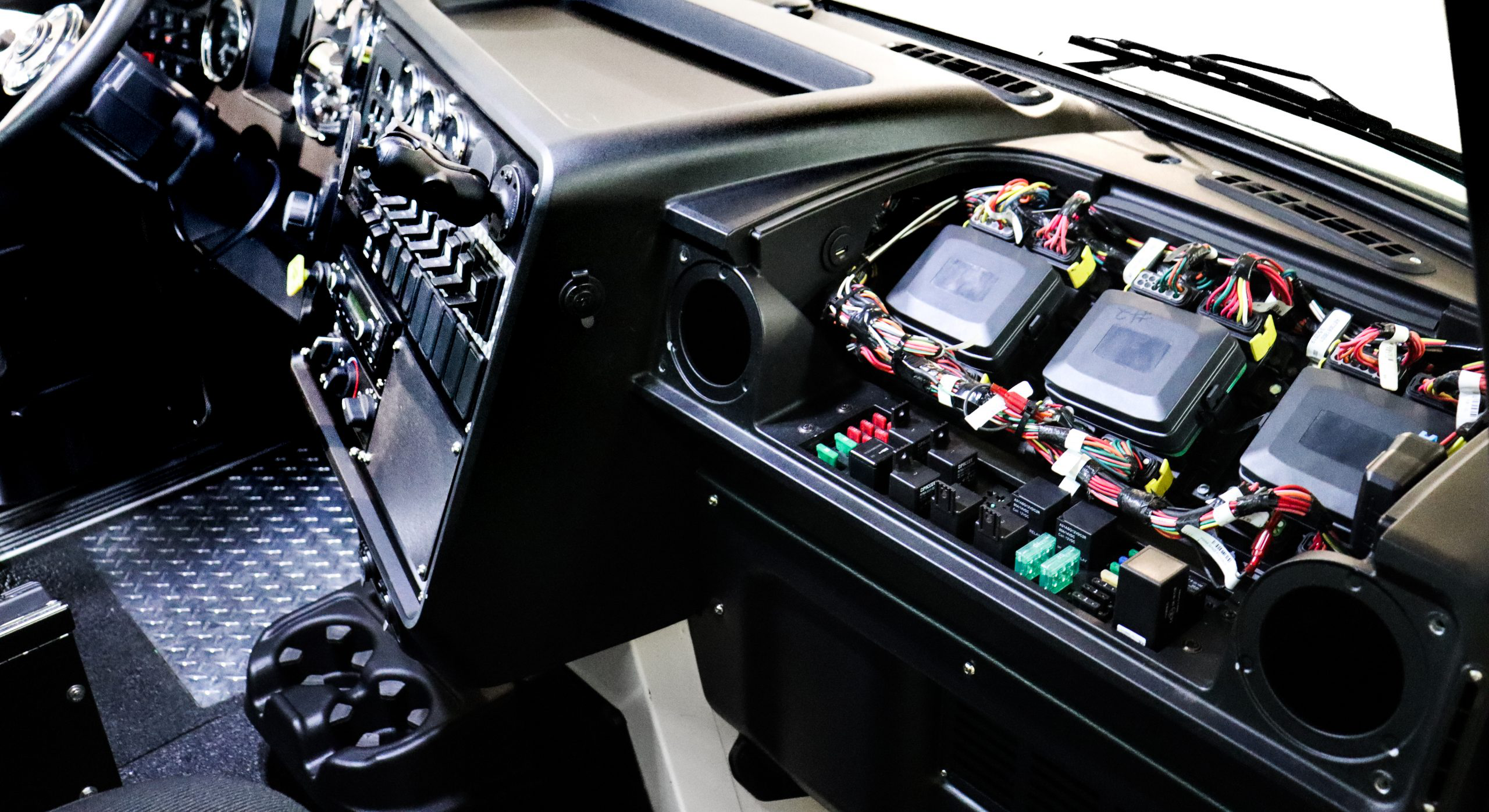

Passenger side electrical fuse boxes provide easy access.

A virtual tech service, available through a phone app, walks customers through easy fixes via videos. “Where it makes sense — such as blown fuse — we allow our customers to self-serve,” Thornton says. Customers are shown where the fuse is and how to replace it. The DC-64D has three smart fuse boxes, accessible on the passenger side.

This service approach is enabled by a premium price on the front end. “Our customers value service and uptime and they’re very big on their drivers,” Thornton says. “They want them in a purpose-built, safe, comfortable environment.”

Construction return

As mentioned, the DC-64D is a return to the conventional dump truck market for a dump trucks charlotte nc that’s now known for its medium and severe-duty cabover models.

Autocar had conventional dump trucks from the 1960s to 1995, including its DC-9964B, now known to scale-model enthusiasts. “The DC-64D really a reincarnation of that vintage truck with a new modern design and look,” Thornton says.

The first DC-64 D will roll off the line in a few weeks; already in production are the rear-discharge mixer DC-64M, the concrete pump DC-64P and DC-64R refuse model.